Is your Carrier air conditioner not blowing cold air? The problem might lie with a small but crucial component: the AC compressor contactor. This often-overlooked device plays a vital role in regulating power to your AC compressor, the heart of your cooling system. Understanding how this electromechanical switch operates can save you from sweltering summer days and costly repairs.

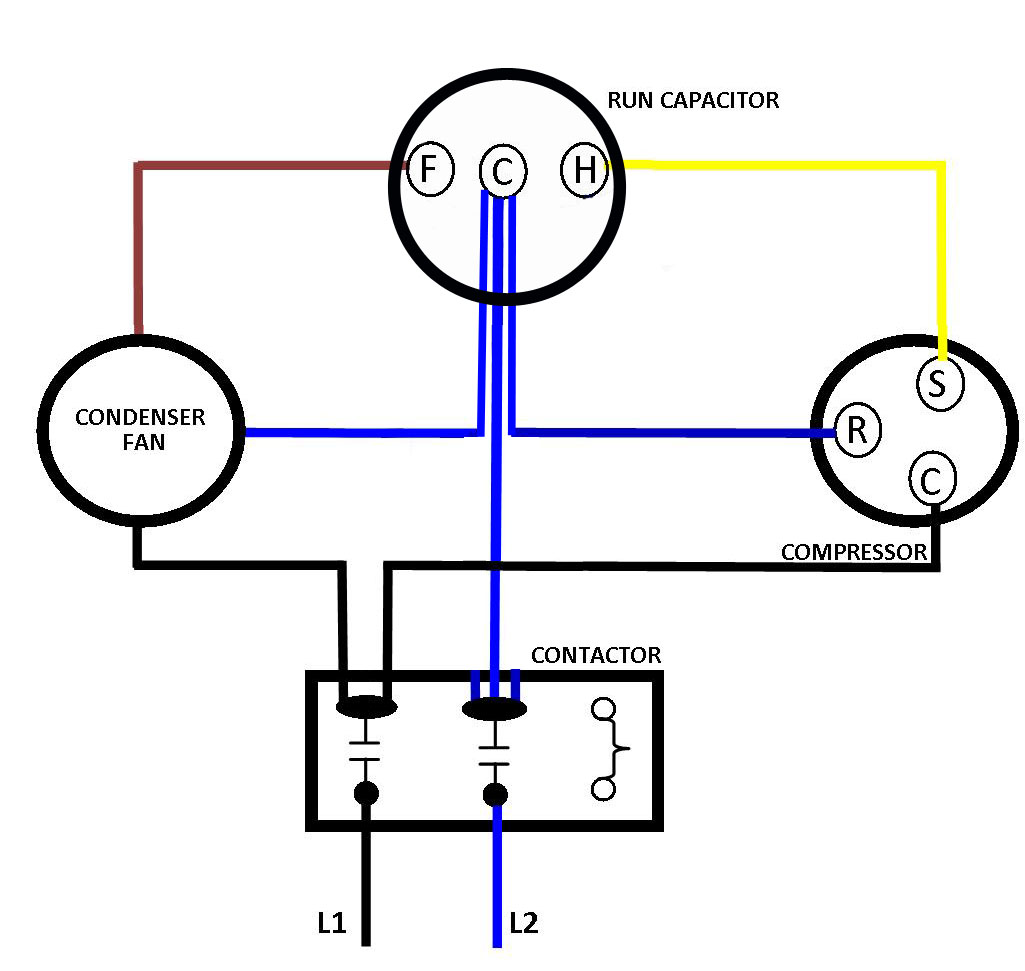

The Carrier AC compressor contactor is essentially an electrical relay that controls the flow of power to the compressor motor. When your thermostat signals a need for cooling, the contactor closes, completing the circuit and allowing electricity to flow to the compressor. This starts the cooling cycle. When the desired temperature is reached, the thermostat signals the contactor to open, cutting off power to the compressor and stopping the cooling process. This cycle of engaging and disengaging ensures efficient cooling and prevents the compressor from running continuously.

While the exact origin of the AC compressor contactor is difficult to pinpoint, its development is intrinsically linked to the evolution of air conditioning technology. As AC systems became more sophisticated, the need for a reliable switching mechanism to control the compressor became evident. The contactor emerged as a robust and efficient solution, enabling precise control over the cooling cycle. Its importance cannot be overstated: without a functioning contactor, your Carrier AC system simply won't cool your home.

A common issue with Carrier AC compressor contactors is sticking or failing to engage. This can be caused by a variety of factors, including electrical issues, mechanical wear and tear, or a faulty coil. A malfunctioning contactor can lead to a variety of problems, from insufficient cooling to complete system failure. Recognizing the symptoms of a bad contactor, such as clicking noises, burnt contacts, or a constantly running compressor, is crucial for timely intervention and preventing further damage.

Understanding the basics of a Carrier air conditioner compressor relay, as it's sometimes called, is essential for any homeowner. This device acts like a gatekeeper for the electrical current flowing to your compressor. Imagine a drawbridge: when the thermostat calls for cooling, the contactor "lowers the bridge," allowing power to flow. When cooling is no longer needed, the contactor "raises the bridge," cutting off the power. This simple yet effective mechanism ensures efficient operation and prolongs the lifespan of your compressor.

One benefit of a properly functioning Carrier AC compressor contactor is energy efficiency. By precisely controlling the compressor's operation, the contactor prevents unnecessary energy consumption, resulting in lower utility bills. Another benefit is enhanced compressor longevity. By preventing the compressor from running continuously, the contactor reduces wear and tear, extending its lifespan. Finally, a reliable contactor ensures consistent cooling performance, keeping your home comfortable even during the hottest days.

Advantages and Disadvantages of Carrier AC Compressor Contactors

| Advantages | Disadvantages |

|---|---|

| Energy Efficiency | Subject to Wear and Tear |

| Extended Compressor Lifespan | Can Malfunction Due to Electrical Issues |

| Consistent Cooling Performance | Requires Periodic Inspection and Maintenance |

Troubleshooting a suspected faulty contactor often involves checking for loose wiring, burnt contacts, and testing the contactor coil with a multimeter. Always consult a qualified HVAC technician for any repairs or replacements to ensure safety and proper functionality.

Frequently Asked Questions:

1. What is a Carrier AC compressor contactor? - It's an electrical switch controlling power to the compressor.

2. What are signs of a bad contactor? - Clicking sounds, burning smells, or lack of cooling.

3. Can I replace a contactor myself? - It's recommended to hire a qualified technician.

4. How much does a replacement contactor cost? - Costs vary, but it's generally an affordable repair.

5. How often should a contactor be inspected? - Ideally, during annual AC maintenance.

6. What causes a contactor to fail? - Electrical surges, mechanical wear, or a faulty coil.

7. How can I prevent contactor issues? - Regular maintenance and surge protection can help.

8. What happens if the contactor is stuck closed? - The compressor will run continuously, potentially overheating.

Tips for maintaining your Carrier AC compressor contactor include ensuring proper voltage supply, keeping the contactor clean and free from debris, and having it inspected by a professional during annual maintenance.

In conclusion, the Carrier AC compressor contactor is a vital component for the efficient and reliable operation of your cooling system. Understanding its function, recognizing signs of potential problems, and ensuring regular maintenance are essential for keeping your home cool and comfortable. By investing in preventative maintenance and addressing issues promptly, you can extend the life of your compressor and avoid costly repairs down the road. Don’t underestimate the importance of this small but mighty component. A properly functioning contactor contributes significantly to the overall performance and longevity of your Carrier AC system. Taking the time to understand its role and addressing potential issues proactively can save you from discomfort and expense in the long run. Contact a qualified HVAC technician today for a thorough system check and ensure your Carrier AC is ready for peak performance.

Ace your california drivers permit test your ultimate guide

Exploring the world of mhm lil tony lyrics

Wind power revolution navigating the us wind farm map