Your boat lift is your vessel's cradle, a mechanical marvel that grants easy access to the water. But when it malfunctions, the dream of effortless boating can quickly turn into a nightmare. Imagine showing up at the lake, ready for a day of sun and spray, only to find your TEC II boat lift unresponsive. This guide delves into the intricacies of TEC II boat lift troubleshooting, equipping you with the knowledge to diagnose and resolve issues, keeping your boat afloat and your boating dreams alive.

TEC II boat lifts are renowned for their reliability and robust construction. However, like any complex electromechanical system, they are prone to occasional hiccups. Understanding the potential problems and their solutions can save you time, money, and frustration. From the whirring of the motor to the gentle hum of the hydraulic system, every component plays a crucial role in the lift’s operation. This guide will help you decipher the language of your TEC II boat lift, translating its mechanical groans and electrical whispers into actionable insights.

Troubleshooting a TEC II boat lift isn't about brute force; it's about methodical investigation. This involves observing the symptoms, understanding the underlying mechanisms, and applying logical deduction to pinpoint the root cause. This guide will equip you with a systematic approach, transforming you from a bewildered boat owner into a confident troubleshooter.

The history of boat lifts parallels the evolution of boating itself. As boats grew larger and more sophisticated, the need for efficient and reliable lifting mechanisms became apparent. TEC II boat lifts represent a significant advancement in this field, incorporating advanced technology and design to provide a smooth and secure lifting experience. Understanding the principles behind these lifts is key to effective troubleshooting.

Common issues with TEC II boat lifts can range from simple electrical glitches to more complex hydraulic malfunctions. A thorough understanding of these issues, their causes, and their solutions is crucial for maintaining the optimal performance of your lift. This guide covers a wide range of potential problems, from faulty limit switches to low hydraulic fluid levels, providing practical solutions for each scenario.

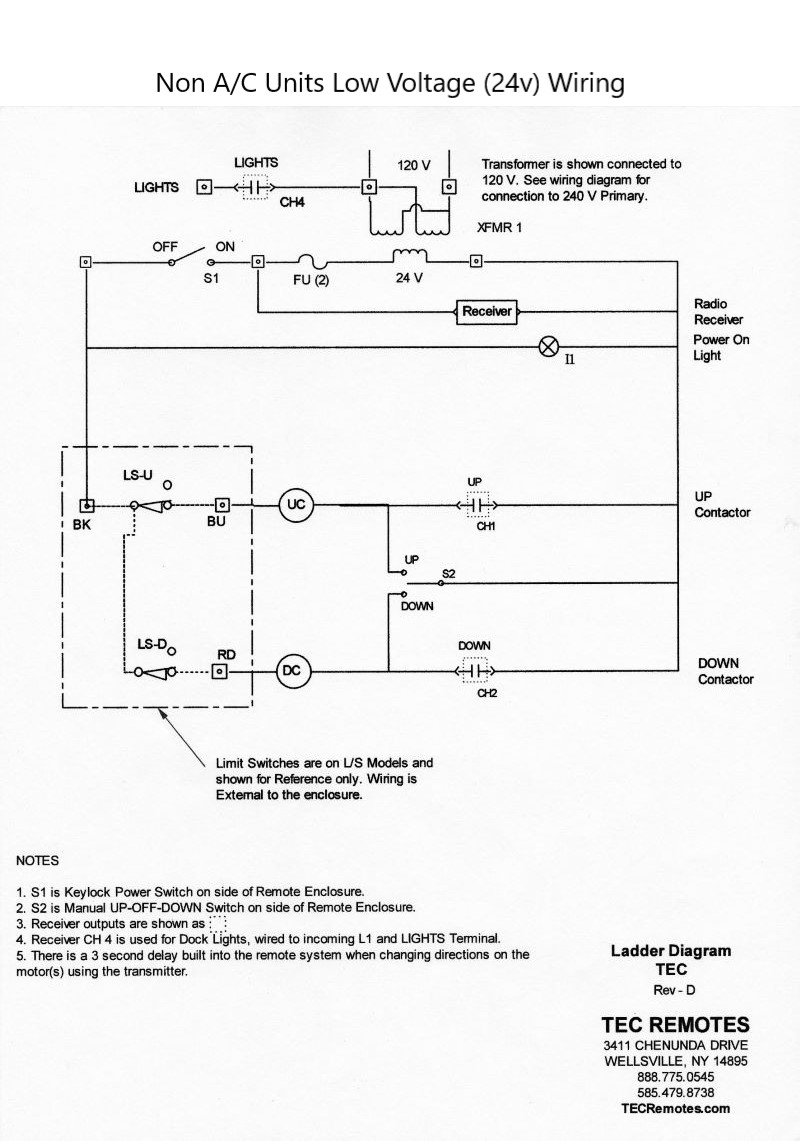

One key aspect of TEC II boat lift troubleshooting involves understanding the function of the limit switches. These switches control the upward and downward movement of the lift, ensuring that it stops at the correct positions. A malfunctioning limit switch can cause the lift to overtravel, potentially damaging the boat or the lift itself.

Benefits of TEC II Boat Lift Troubleshooting:

1. Cost Savings: By identifying and fixing minor issues early on, you can prevent more extensive and costly repairs down the line. For example, addressing a low hydraulic fluid level can prevent damage to the hydraulic pump, saving you hundreds of dollars.

2. Increased Lifespan: Regular troubleshooting and preventative maintenance can significantly extend the life of your TEC II boat lift. By keeping the system in good working order, you can avoid premature wear and tear.

3. Enhanced Safety: A properly functioning boat lift is essential for safe boating. By troubleshooting and addressing any issues promptly, you can ensure the safety of your boat, your passengers, and your dock.

Troubleshooting Checklist:

- Check power supply and circuit breaker

- Inspect limit switches for proper function

- Check hydraulic fluid levels

- Examine cables and pulleys for wear and tear

- Listen for unusual noises during operation

Advantages and Disadvantages of DIY TEC II Boat Lift Troubleshooting

| Advantages | Disadvantages |

|---|---|

| Cost savings on service calls | Risk of misdiagnosis and further damage |

| Quick resolution of minor issues | Potential for injury if safety precautions are not followed |

| Increased understanding of your lift's operation | May void warranty if improper repairs are attempted |

Best Practices:

1. Regular Inspection: Perform visual inspections of your TEC II boat lift regularly, looking for signs of wear, damage, or loose components.

2. Lubrication: Keep moving parts properly lubricated to minimize friction and wear.

3. Hydraulic Fluid Check: Monitor the hydraulic fluid level and top it off as needed.

4. Electrical Connections: Ensure all electrical connections are secure and free from corrosion.

5. Professional Service: For complex issues or if you are unsure about any aspect of troubleshooting, consult a qualified TEC II boat lift technician.

FAQ:

1. Why is my TEC II boat lift not lifting? (Possible causes: power outage, tripped breaker, faulty limit switch, low hydraulic fluid)

2. Why is my boat lift making a grinding noise? (Possible causes: worn bearings, damaged gears, loose components)

3. How often should I check the hydraulic fluid? (At least once a month, or more frequently if you notice any leaks)

4. Can I use any type of hydraulic fluid? (No, use only the type of hydraulic fluid recommended by the manufacturer.)

5. What should I do if my boat lift is stuck? (Immediately disconnect the power and contact a qualified technician.)

6. How can I prevent corrosion on my boat lift? (Regularly rinse the lift with fresh water, especially after use in saltwater.)

7. How do I reset a tripped breaker? (Locate the breaker box and flip the tripped breaker back to the "on" position.)

8. What are the signs of a worn cable? (Fraying, kinks, or rust are indicators of a worn cable.)

Tips and Tricks: Keep a logbook of maintenance activities and any repairs performed on your TEC II boat lift. This will help you track the lift’s history and identify any recurring problems. Also, consider investing in a boat lift cover to protect it from the elements and extend its lifespan.

In conclusion, mastering the art of TEC II boat lift troubleshooting empowers you to maintain your lift's performance, extend its lifespan, and ensure safe and enjoyable boating experiences. By understanding the intricacies of the system, recognizing common problems, and implementing preventative maintenance practices, you can keep your boat lift running smoothly for years to come. Remember, regular inspection, prompt attention to any issues, and adherence to the manufacturer’s recommendations are key to maximizing the reliability and longevity of your TEC II boat lift. Investing time and effort in understanding your TEC II boat lift's operation and troubleshooting procedures will ultimately save you time, money, and frustration, allowing you to focus on what matters most: enjoying your time on the water. Don't let a malfunctioning boat lift sink your boating plans. Take proactive steps to ensure your TEC II boat lift remains a reliable and essential part of your boating lifestyle.

Decoding dometic ac wiring your chilling guide

Printable cover pages transform your documents

Conestoga college doon campus programs your future starts here