Ever filled up your car and thought, “Wait, where’s the gas cap?” You’re not alone! Many modern vehicles now sport capless fuel systems, a seemingly magical innovation that streamlines refueling. But this convenience comes with its own set of maintenance requirements. Just because there’s no cap to twist off doesn’t mean it’s maintenance-free. In fact, keeping this hidden system clean is crucial for your car’s performance.

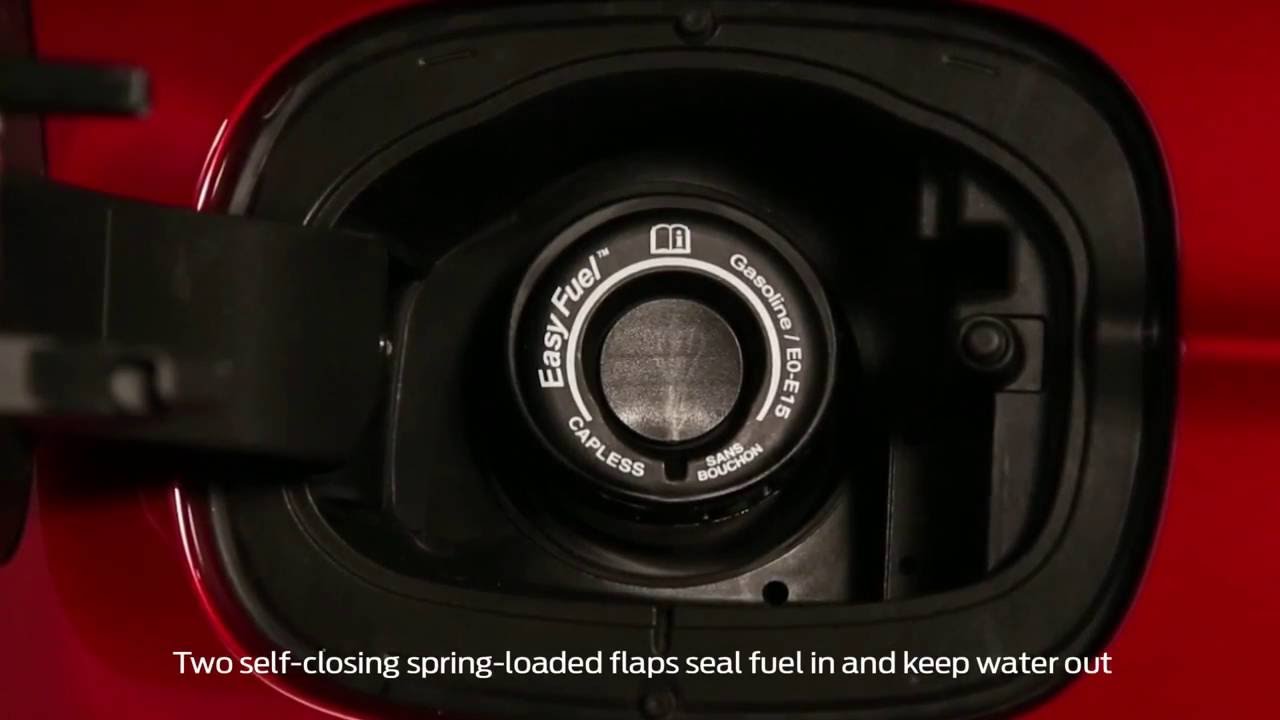

Capless fuel fillers, also known as EasyFuel or capless fuel tanks, might seem futuristic, but they've been around for a while now. Ford pioneered the technology back in 2008, aiming to simplify refueling and reduce evaporative emissions. Other manufacturers quickly followed suit, and now you can find capless fuel systems on a wide range of vehicles. So why the need for cleaning? These systems, while ingenious, can be susceptible to dirt, debris, and even fuel spills, potentially leading to performance issues down the line.

The importance of capless fuel filler maintenance often goes unnoticed. Drivers accustomed to traditional gas caps might overlook the need to care for this seemingly self-sufficient system. However, neglecting its cleanliness can lead to several problems, from difficulty fueling to more serious mechanical issues. Dust, dirt, and road grime can accumulate around the fuel filler opening and eventually find their way into the fuel system. This contamination can clog filters, affect fuel pump operation, and even impact engine performance.

Imagine this: You pull up to the gas station, ready to fill up, but the fuel nozzle won't insert properly. Or worse, your check engine light illuminates. These scenarios can be the direct result of a neglected capless fuel filler. Keeping the area clean prevents such issues and ensures the longevity of your vehicle’s fuel system. Think of it as a small investment of time that can save you from costly repairs and headaches down the road.

So, what exactly does maintaining a capless fuel filler entail? It’s more than just wiping away visible dirt. It involves regular inspection and cleaning to prevent the buildup of debris and ensure the smooth operation of the intricate spring-loaded flapper valve that seals the system. This small but vital component protects your fuel tank from contaminants and prevents fuel vapors from escaping.

Early capless designs faced issues like sticking flapper valves, often due to debris or fuel residue buildup. Modern systems have addressed many of these issues, but regular cleaning remains crucial for optimal performance.

A capless fuel filler system typically consists of a spring-loaded flapper valve that seals the fuel tank opening. When the fuel nozzle is inserted, it pushes open the flapper valve, allowing fuel to flow into the tank. Once the nozzle is removed, the flapper valve springs back, sealing the tank.

Advantages and Disadvantages of Capless Fuel Fillers

| Advantages | Disadvantages |

|---|---|

| Convenience: No more fumbling with gas caps. | Potential for debris buildup: Requires regular cleaning. |

| Reduced evaporative emissions: Environmentally friendly. | Possible malfunction of the flapper valve: Can lead to fueling difficulties. |

Best Practices: Regularly inspect the fuel filler area for debris. Use a clean microfiber cloth to wipe away any dirt or grime. Avoid using sharp objects that could damage the flapper valve. If you spill fuel, clean it up immediately.

FAQs:

Q: How often should I clean my capless fuel filler? A: It's recommended to inspect and clean it every few months or as needed.

Maintaining a clean capless fuel filler isn’t just about keeping your car looking its best; it’s about ensuring the smooth and efficient operation of a vital component. By taking the time to regularly inspect and clean your capless fuel system, you’re not only preventing potential problems but also extending the life of your vehicle. It's a small act of care that can have a big impact on your car's performance and your peace of mind.

Finding your dream pre owned bmw in greenville sc

Choosing the right circuit breaker brand a comprehensive guide

Free job offer letter templates word streamlined hiring