Ever find yourself staring at a Piping and Instrumentation Diagram (P&ID) and wondering what those cryptic symbols mean? It's like deciphering a secret code, right? Well, today we're cracking the code of one crucial symbol: the TP, representing a combined temperature and pressure measurement instrument.

Imagine building a house without a blueprint. Chaos, right? Similarly, in the industrial world, P&IDs are the blueprints for process plants. They're the visual language engineers and operators use to understand complex systems. And within this language, each symbol, including the TP symbol, holds vital information.

The TP symbol is essentially shorthand for a single instrument that measures both temperature and pressure. It simplifies the diagram, avoiding the need for separate temperature (T) and pressure (P) indicators. This combined measurement is often crucial for process control and safety. Think of a pressure cooker – knowing both temperature and pressure is essential for safe operation. Similarly, in many industrial processes, the interplay of temperature and pressure determines the reaction, efficiency, and safety of the entire operation.

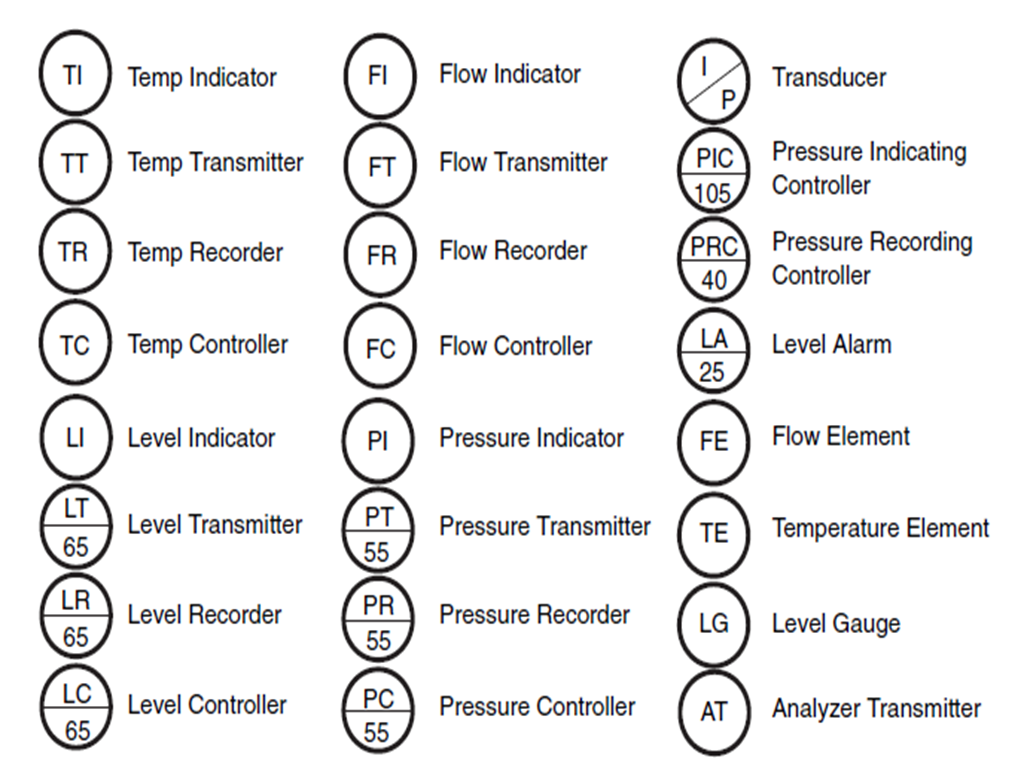

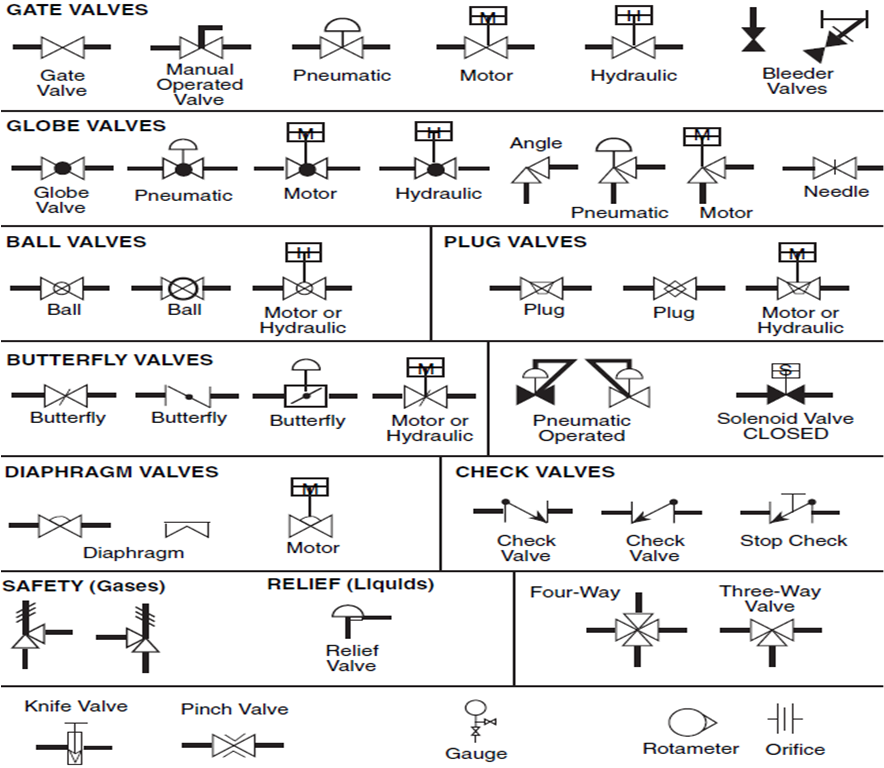

While the exact origin of the TP symbol is difficult to pinpoint, its usage is standardized across various industries through organizations like ISA (International Society of Automation). This standardization is crucial for clear communication and prevents misinterpretations that can lead to costly errors or safety hazards. Imagine different countries using different words for "stop" – confusion could be disastrous. Standardized P&ID symbols, including TP, prevent this kind of confusion in the industrial world.

Understanding the TP symbol isn't just about knowing what it represents. It’s about grasping its significance within the larger context of the process. Misinterpreting this symbol can have serious consequences, from inefficient operations to potential safety risks. For example, incorrect readings from a malfunctioning TP instrument could lead to improper temperature or pressure control, impacting product quality or even causing equipment damage.

The TP symbol indicates a dual-function instrument recording both temperature and pressure at a specific point in the process. For example, in a steam boiler, a TP element might be placed at the outlet to ensure the steam is at the correct temperature and pressure for its intended use.

Benefits of using a TP symbol include: simplified diagrams, reduced instrument costs, and improved process monitoring.

To ensure accurate readings, calibrate your TP instruments regularly and check for any signs of damage or malfunction. If you encounter inconsistencies, consult the P&ID and instrument manuals for troubleshooting.

Advantages and Disadvantages of Combined TP Instruments

While combining temperature and pressure measurement into a single instrument can be beneficial, it also presents certain drawbacks:

| Advantages | Disadvantages |

|---|---|

| Reduced cost compared to separate instruments | Single point of failure – if the combined instrument fails, you lose both temperature and pressure readings |

| Space-saving on the P&ID and in the physical installation | May not be suitable for all applications where highly precise individual measurements are required |

| Simplified process monitoring | More complex calibration and maintenance procedures compared to single-function instruments |

Frequently Asked Questions:

1. What does TP stand for in a P&ID? - Temperature and Pressure

2. Why use a combined TP instrument? - For cost savings and simplified design.

3. How are TP instruments calibrated? - Calibration procedures vary depending on the specific instrument and manufacturer's guidelines.

4. What are common issues with TP instruments? - Sensor drift, calibration issues, and physical damage.

5. How often should TP instruments be calibrated? - Calibration frequency depends on the application and regulatory requirements.

6. What are alternatives to TP instruments? - Separate temperature and pressure instruments.

7. Where can I find more information on P&ID symbols? - ISA standards and engineering handbooks.

8. Are there different types of TP instruments? - Yes, various manufacturers offer different models with varying features and specifications.

Tips and Tricks: Always cross-reference the TP symbol with the instrument list on the P&ID for detailed specifications. Regular maintenance and calibration are essential for accurate and reliable measurements.

In conclusion, the TP symbol in P&IDs represents a powerful tool for efficient process monitoring and control. It simplifies diagrams, reduces costs, and provides crucial data for safe and efficient operation. While combined TP instruments offer numerous benefits, it's crucial to understand their limitations and choose the right instrument for your specific needs. Mastering the language of P&IDs, including understanding symbols like the TP, is essential for anyone working in the process industries. By understanding the nuances of these symbols, you can unlock the secrets of complex processes and contribute to safer, more efficient operations. So, the next time you encounter a TP symbol, you'll know it's more than just a simple marking – it's a vital piece of information that keeps the industrial world running smoothly.

Unlocking the elegance of exquisite cursive fonts

Elevated essentials the allure of high waisted straight leg scrub pants

A royal union prince william and kates wedding date