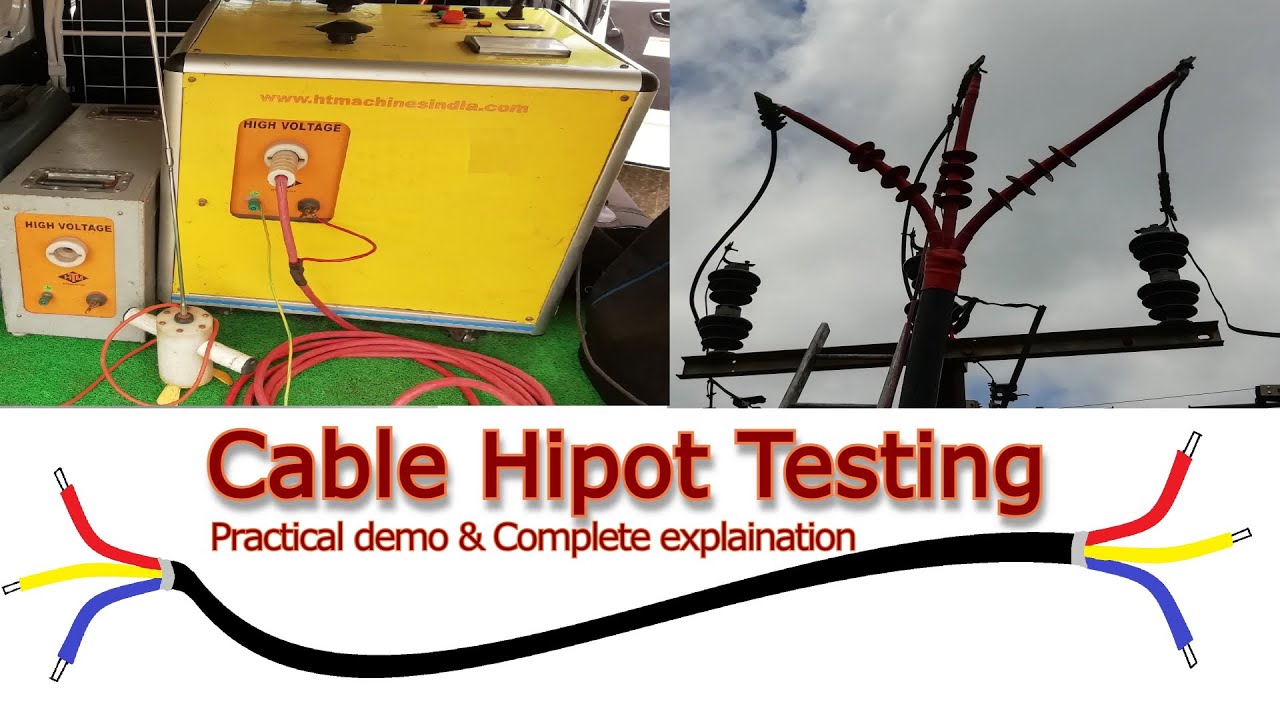

Imagine a world where electrical devices malfunction without warning, posing constant risks of shock and fire. This nightmare scenario is precisely what high-potential (hipot) testing aims to prevent. At the heart of this critical safety procedure lies the hipot test circuit diagram – a blueprint for ensuring the integrity of electrical insulation. This article delves into the intricacies of this often-overlooked but essential aspect of electrical safety.

The hipot test, also known as a dielectric withstand test or high voltage insulation resistance test, involves applying a high voltage to an electrical device or component to verify the adequacy of its insulation. This test ensures that the insulation can withstand the stresses of everyday use and prevent dangerous current leakage. The hipot test circuit diagram provides the roadmap for conducting this test safely and effectively, outlining the connections, components, and safety measures required.

While the precise origins of the hipot test are difficult to pinpoint, its development is closely tied to the rise of electricity in the late 19th and early 20th centuries. As electrical systems became more complex and widespread, the need for rigorous safety testing became paramount. Early hipot testing likely involved rudimentary setups, but over time, standardized procedures and dedicated equipment emerged, leading to the development of formalized hipot test circuit diagrams.

Understanding a hipot tester circuit diagram is crucial for anyone working with electrical devices. It's the key to conducting the test correctly, ensuring reliable results, and maintaining safety. A typical diagram outlines the connections between the hipot tester, the device under test (DUT), and the ground. It also specifies the required voltage and current limits, as well as any necessary safety precautions.

Misinterpreting or neglecting aspects of the hipot tester schematic can lead to inaccurate test results, equipment damage, or even personal injury. Therefore, a thorough understanding of the diagram is essential for both designing and executing a safe and effective hipot test. Ignoring safety protocols, using incorrect voltage levels, or improperly grounding the circuit can have serious consequences.

One key benefit of high-potential testing, guided by its circuit diagram, is the detection of insulation weaknesses. By stressing the insulation with a high voltage, the test can reveal flaws that might not be apparent under normal operating conditions. For example, a cable with a small nick in its insulation might function normally at low voltages but could break down and cause a short circuit when subjected to the higher voltage of a hipot test.

Another advantage of using high-potential testing with a proper circuit layout is the prevention of electrical shocks. By ensuring that the insulation is adequate, the test minimizes the risk of current leakage that could lead to electric shock hazards for users. This is particularly crucial for devices that come into direct contact with humans, such as appliances, power tools, and medical equipment.

Finally, hipot testing, conducted according to the prescribed circuit design, enhances product reliability. By identifying and eliminating insulation weaknesses early in the manufacturing process, the test helps prevent premature failures and ensures the long-term reliability of electrical products. This contributes to increased customer satisfaction and reduced warranty costs.

Advantages and Disadvantages of Hipot Testing

| Advantages | Disadvantages |

|---|---|

| Improved Safety | Potential for damaging sensitive components if not done correctly. |

| Increased Reliability | Can be time-consuming, particularly for complex devices. |

| Reduced Warranty Costs | Requires specialized equipment and trained personnel. |

Best Practices for Hipot Testing:

1. Always refer to the specific hipot test circuit diagram for the device being tested.

2. Ensure proper grounding of the circuit to prevent electrical shocks.

3. Use the correct voltage and current limits as specified in the diagram.

4. Wear appropriate safety gear, including insulated gloves and eye protection.

5. De-energize and disconnect the DUT before connecting the hipot tester.

Frequently Asked Questions:

1. What is a hipot test? A hipot test checks the integrity of electrical insulation.

2. Why is hipot testing important? It ensures electrical safety and product reliability.

3. What is a hipot test circuit diagram? It outlines the setup for a hipot test.

4. What are the risks of improper hipot testing? Equipment damage, inaccurate results, or injury.

5. What precautions should be taken during hipot testing? Follow safety guidelines and the circuit diagram.

6. How often should hipot testing be performed? Depends on the application and industry standards.

7. What equipment is needed for a hipot test? A hipot tester, test leads, and safety gear.

8. Where can I find more information on hipot testing? Consult industry standards and manufacturer guidelines.

In conclusion, the hipot test circuit diagram plays a critical role in ensuring the safety and reliability of electrical devices. Understanding and adhering to the diagram is paramount for conducting accurate tests, preventing accidents, and upholding high standards of quality. From its historical roots to its modern applications, the hipot test stands as a testament to the importance of thorough testing in a world increasingly reliant on electricity. This proactive approach to safety not only protects users but also minimizes the risk of costly product failures. Embracing best practices and continually seeking to improve testing methodologies are essential steps in ensuring a safer and more reliable electrical future.

Unlocking longevity secrets from scripture

Exploring the nuances of pink with sherwin williams

Unlocking perfect paint colors with sherwin williams color matching