Got a trailer? Then you've got wheel bearings, and if they're Dexter axle wheel bearings, you're in the right place. These small but mighty components are crucial for a safe and smooth towing experience. Ignoring them can lead to costly repairs, or worse, a dangerous situation on the road. This guide will walk you through everything you need to know about Dexter axle wheel bearings, from routine checks to complex troubleshooting.

Imagine this: you're cruising down the highway, enjoying the open road, when suddenly you hear a grinding noise coming from your trailer. That, my friend, could be the sound of a failing wheel bearing. Dexter axle wheel bearings, like any other bearings, are subject to wear and tear. They're the unsung heroes that allow your wheels to rotate freely, supporting the weight of your trailer and its cargo. Without properly functioning bearings, your trip could come to a screeching halt – literally.

Dexter has long been a trusted name in the trailer industry, known for producing reliable and durable axles. Their wheel bearings are no exception. They are designed to withstand the rigors of the road, providing consistent performance under various conditions. Understanding how these bearings work, how to maintain them, and what signs to look out for can save you time, money, and potential headaches down the road.

Dexter axle wheel bearing maintenance isn't glamorous, but it's essential. Regular inspection and repacking with high-quality grease are key to extending their lifespan. Neglecting these simple tasks can lead to premature wear, overheating, and ultimately, bearing failure. This guide will equip you with the knowledge to keep your Dexter axle wheel bearings in top shape, ensuring countless miles of trouble-free towing.

From understanding the different types of Dexter axle wheel bearings to mastering the art of repacking them, this comprehensive resource is your one-stop shop for all things related to Dexter axle wheel bearing maintenance and repair. So, buckle up and get ready to learn how to keep your trailer rolling smoothly and safely for years to come.

The history of Dexter Axle dates back to 1960, when the company was founded. Since then, they've become a leading manufacturer of trailer axles and related components. The importance of Dexter axle wheel bearings lies in their function: they minimize friction between the rotating wheel and the stationary axle, enabling smooth and efficient movement. A main issue related to Dexter axle wheel bearings, like any wheel bearing, is wear and tear due to friction, heat, and road debris. Regular maintenance is crucial to prevent these issues.

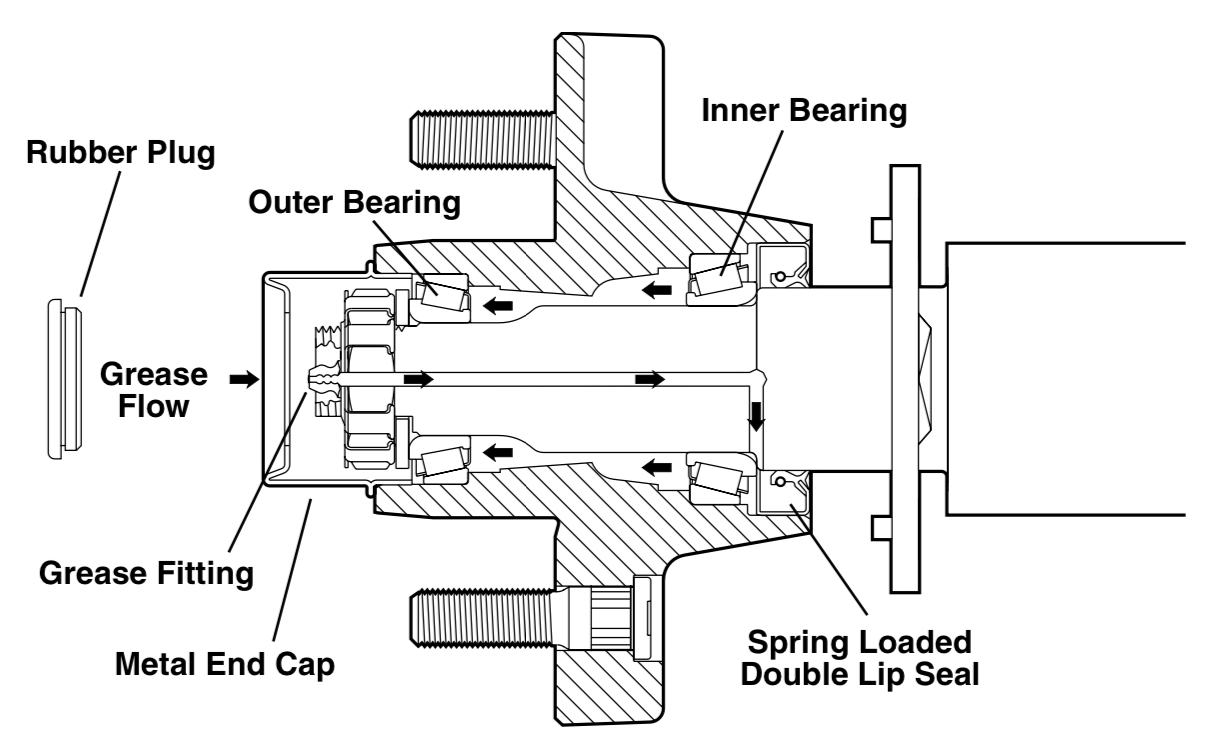

Dexter axle wheel bearings are precision-engineered components consisting of an inner and outer race, rolling elements (typically rollers or balls), and a cage to keep the rolling elements evenly spaced. These components work together to reduce friction and allow the wheel to rotate freely.

Benefits of using quality Dexter axle wheel bearings include: 1) Improved fuel efficiency due to reduced rolling resistance. 2) Extended tire life as properly lubricated bearings minimize friction and heat buildup. 3) Enhanced safety as well-maintained bearings reduce the risk of wheel failure.

Advantages and Disadvantages of Dexter Axle Wheel Bearings

| Advantages | Disadvantages |

|---|---|

| Durability | Require regular maintenance |

| Wide availability | Can be expensive to replace |

| Reliable performance | Susceptible to damage from water and debris |

Best Practices for Dexter Axle Wheel Bearing Maintenance:

1. Inspect bearings regularly for signs of wear or damage.

2. Repack bearings with high-quality grease every 12 months or 12,000 miles.

3. Use a bearing packer to ensure proper grease distribution.

4. Clean bearings thoroughly before repacking.

5. Replace worn or damaged bearings immediately.

Frequently Asked Questions:

1. How often should I repack my Dexter axle wheel bearings? Generally, every 12 months or 12,000 miles.

2. What type of grease should I use? A high-quality, lithium-based wheel bearing grease.

3. How do I know if my bearings are bad? Signs include grinding noises, excessive heat, and play in the wheel.

4. Can I repack my bearings myself? Yes, with the right tools and knowledge.

5. What tools do I need to repack bearings? A bearing packer, grease, wrenches, and a hammer.

6. How much does it cost to replace a Dexter axle wheel bearing? Costs vary but typically range from $50 to $150 per bearing.

7. Where can I buy Dexter axle wheel bearings? At most auto parts stores and trailer supply retailers.

8. What are the common sizes of Dexter axle wheel bearings? Sizes vary depending on the axle capacity and design, consult your Dexter Axle manual for specifics.

Tips and Tricks: When repacking bearings, ensure they are completely filled with grease. Inspect the seals for any damage and replace them if necessary.

In conclusion, Dexter axle wheel bearings are essential components for safe and efficient trailer operation. Regular maintenance, including inspection and repacking, is crucial for preventing premature wear and potential failures. Understanding the function, importance, and maintenance requirements of these bearings will not only save you money in the long run but also provide peace of mind on the road. By following the best practices outlined in this guide and addressing any issues promptly, you can ensure your trailer travels smoothly and safely for years to come. Don’t underestimate the importance of these small but crucial components – your next adventure depends on them. Invest the time and effort to maintain your Dexter axle wheel bearings, and you’ll be rewarded with countless miles of worry-free towing.

Transform your bathroom with stunning wall tiles

Hacking your instagram handle the ultimate username guide

Checking your public bank car loan balance