Creating dilute nitric acid solutions requires careful attention to detail and a strong understanding of safety protocols. This process, though seemingly straightforward, demands precision and respect for the potent nature of the chemicals involved. Are you ready to delve into the specifics of nitric acid dilution?

Diluting nitric acid is a common practice in various scientific, industrial, and educational settings. Its applications range from metal etching and laboratory analyses to pH adjustments and specialized chemical syntheses. Understanding the proper methods for dilution is crucial, as incorrect procedures can lead to hazardous situations.

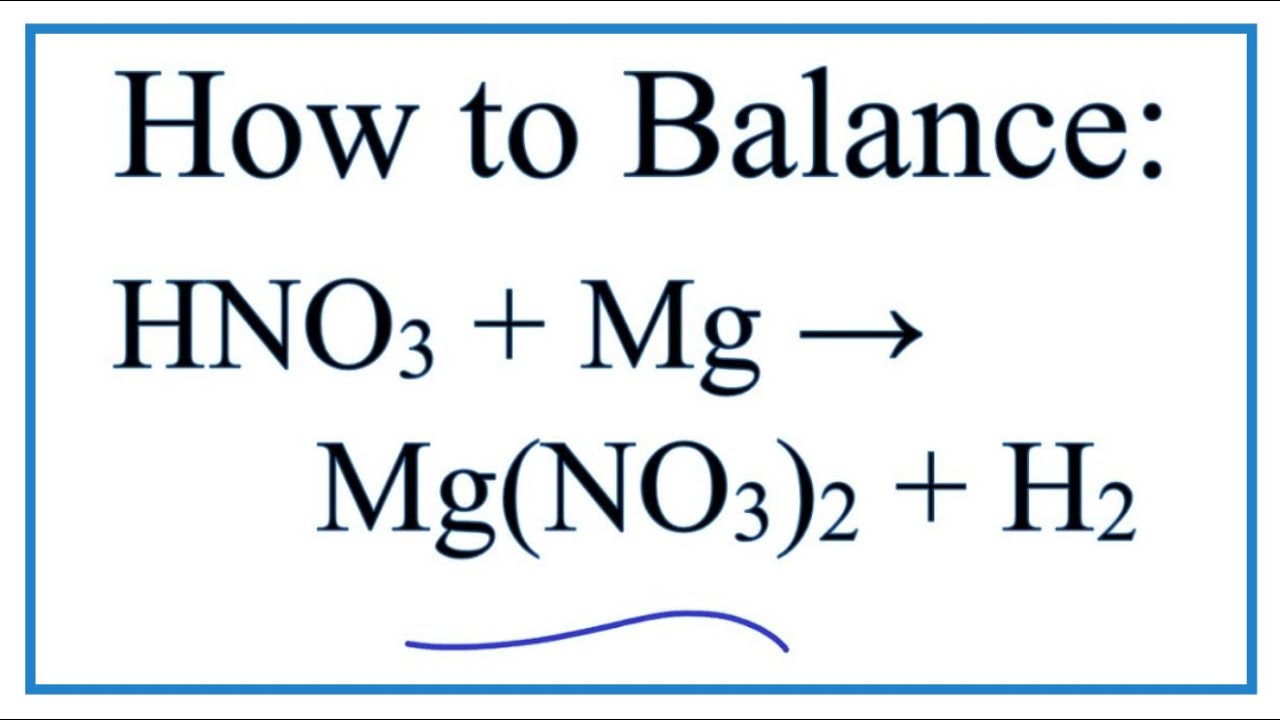

Historically, nitric acid, in various forms, has been known for centuries. Early alchemists experimented with its potent reactive properties. Today, producing dilute nitric acid solutions from concentrated nitric acid is a standard procedure. The core process involves carefully adding the concentrated acid to water, never the reverse. This sequence is critical for managing the heat generated during the dilution process.

The importance of proper nitric acid dilution stems from the inherent dangers associated with concentrated nitric acid. It is a strong oxidizing agent and a highly corrosive substance. Contact with skin or eyes can cause severe burns. Inhaling its fumes can lead to respiratory problems. Therefore, preparing dilute nitric acid safely is paramount to prevent accidents and ensure a controlled, predictable outcome.

One of the primary challenges associated with diluting nitric acid is the exothermic nature of the reaction. When concentrated nitric acid is mixed with water, it releases a significant amount of heat, which can cause the solution to boil and splatter, potentially leading to acid burns. Another key issue is the potential for fume generation. Nitric acid, particularly when concentrated, can release noxious nitrogen dioxide fumes, which are highly irritating and toxic.

Diluting nitric acid involves adding the concentrated acid to water slowly and steadily while constantly stirring the mixture. The water absorbs the heat generated during the dilution process, preventing dangerous temperature spikes. The amount of water and concentrated acid used depends on the desired concentration of the dilute nitric acid solution.

Three key benefits arise from knowing how to prepare dilute nitric acid solutions correctly: enhanced safety, precise control over concentration, and wider applicability. Safely diluting acid minimizes the risk of accidents. Accurate dilution ensures the desired concentration for specific applications. And finally, the ability to prepare dilute solutions expands the range of potential uses for nitric acid.

Creating a step-by-step guide emphasizes safety: Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and a lab coat. Work in a well-ventilated area or under a fume hood. Add the acid to the water slowly and with continuous stirring. Never add water to the acid, as this can cause violent splattering.

Checklist for Diluting Nitric Acid:

PPE (Gloves, Goggles, Lab Coat)

Well-Ventilated Area/Fume Hood

Concentrated Nitric Acid

Distilled or Deionized Water

Volumetric Flask or Graduated Cylinder

Stirring Rod

Advantages and Disadvantages of Preparing Dilute Nitric Acid

| Advantages | Disadvantages |

|---|---|

| Precise Control Over Concentration | Risk of Chemical Burns if not handled carefully |

| Wider Applicability for Various Uses | Potential for Inhalation of Noxious Fumes |

| Cost-Effective Compared to Purchasing Pre-Made Solutions | Requires Proper Storage of Concentrated Nitric Acid |

Five Best Practices: 1. Always add acid to water. 2. Use appropriate PPE. 3. Work in a well-ventilated area. 4. Stir continuously during dilution. 5. Calculate required volumes precisely.

FAQ: 1. What is the molar mass of nitric acid? (63.01 g/mol) 2. What are the uses of dilute nitric acid? (metal cleaning, fertilizer production, etc.) 3. Why is it important to add acid to water and not vice versa? (exothermic reaction safety) 4. What are the hazards of nitric acid? (corrosive, oxidizing agent) 5. How should nitric acid spills be handled? (neutralize with appropriate base) 6. What is the chemical formula of nitric acid? (HNO3) 7. What concentration of nitric acid is considered concentrated? (typically 68-70%) 8. How do you store nitric acid? (cool, dry place away from incompatible materials).

Tips: Use a graduated cylinder or volumetric flask for precise measurements. Label the prepared dilute nitric acid solution clearly with its concentration.

In conclusion, preparing dilute nitric acid solutions is a fundamental skill in many scientific and industrial settings. The process requires meticulous attention to detail, adherence to established safety procedures, and a clear understanding of the chemical reactions involved. Mastering this technique enables greater control over experimental conditions, expands the range of applications for nitric acid, and minimizes the potential for accidents. By understanding the underlying principles and following the recommended practices, you can safely and effectively harness the power of dilute nitric acid for a wide range of purposes. Remember, safety is paramount when working with any chemical, particularly a strong acid like nitric acid. Always prioritize safe handling practices and consult with experienced professionals if you have any doubts or questions. Accurate dilution is not just about achieving the desired concentration; it's about ensuring a safe working environment and successful experimental outcomes.

Perfect white paint sherwin williams colors online guide

The hilarious world of human dog memes

Keeping cool on the road rv ac repair and parts