Ever felt a subtle wobble in your Jeep Wrangler's steering? Or perhaps a disconcerting vibration while cruising down the highway? The culprit could be something as seemingly insignificant as improperly torqued lug nuts. Overlooking this crucial aspect of wheel maintenance can lead to serious safety hazards, from loose wheels to rotor damage. Understanding and applying the correct Wrangler lug nut torque is paramount for a secure and enjoyable driving experience.

Proper wheel attachment on a Jeep Wrangler hinges on achieving the correct lug nut torque. This seemingly simple task plays a vital role in ensuring the safety and performance of your vehicle. Incorrect torque can result in a variety of issues, ranging from stripped studs to detached wheels, jeopardizing your safety and potentially causing significant damage. This guide will delve into the intricacies of Wrangler lug nut torque, providing you with the knowledge and tools to maintain your vehicle effectively.

The specified torque value for Jeep Wrangler lug nuts is not an arbitrary number. It's meticulously engineered to ensure the wheel is securely fastened to the hub while preventing damage to the studs, rotors, and wheels themselves. Applying the correct tightening force distributes the clamping load evenly across all lug nuts, crucial for maintaining wheel integrity and preventing warping or cracking. This balance of secure attachment and damage prevention is the cornerstone of correct lug nut torque.

The importance of correct Wrangler lug nut tightening cannot be overstated. It’s a critical safety measure that directly impacts the stability and control of your vehicle. Think of it as the linchpin holding your wheels firmly in place, preventing potential disasters on the road. Ignoring this fundamental aspect of vehicle maintenance can lead to a cascade of problems, ranging from minor inconveniences to severe accidents.

While seemingly straightforward, the process of tightening lug nuts on a Jeep Wrangler requires a methodical approach. Simply cranking them down as tight as possible is a recipe for disaster. Over-tightening can strip the threads, warp the rotors, or even damage the wheels themselves. Under-tightening, on the other hand, leaves the wheels vulnerable to loosening, potentially leading to detachment while driving. The key lies in achieving the precise torque specification recommended by the manufacturer.

Historically, lug nut torque specifications have evolved alongside advancements in automotive engineering and materials science. Early vehicles relied on simpler designs and less precise fastening methods. With the advent of more complex suspension systems and higher performance demands, the importance of accurate torque specifications became increasingly apparent. Today, manufacturers provide detailed guidelines for achieving optimal wheel attachment, ensuring both safety and performance.

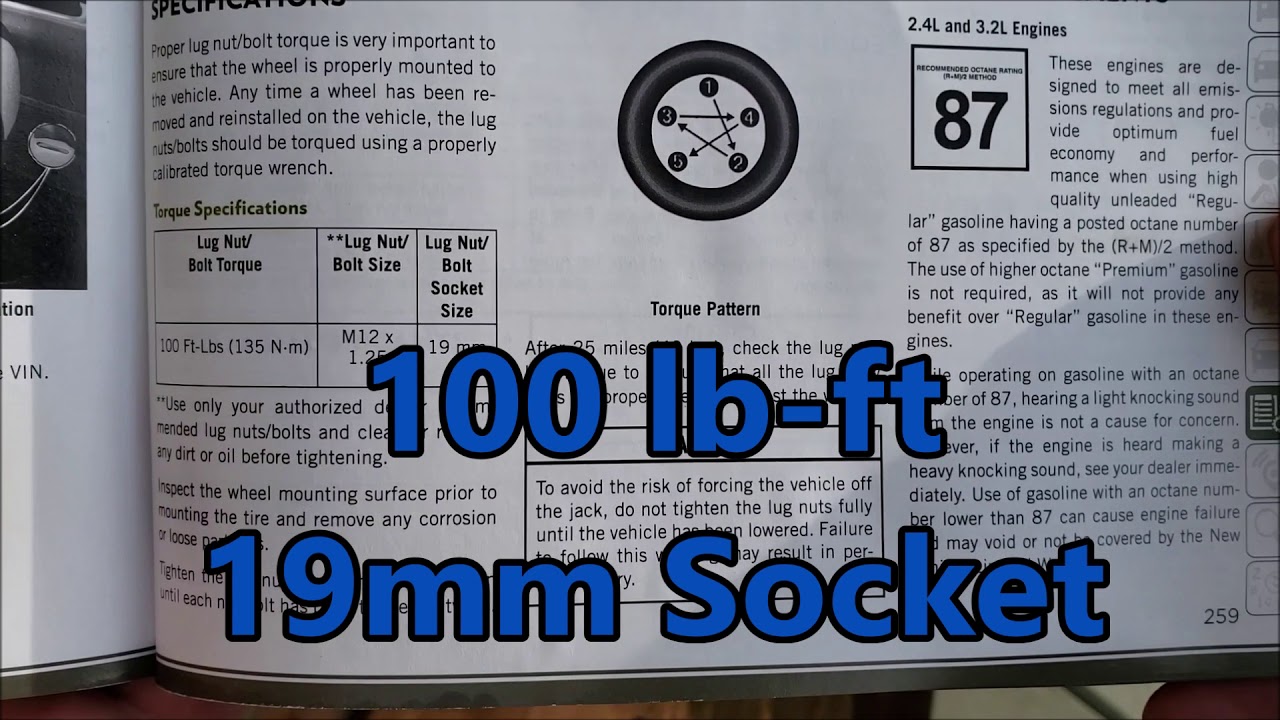

Wrangler lug nut torque specifications can vary depending on the specific model and year. It’s crucial to consult your owner’s manual for the precise recommended torque value. Typically, this value falls within the range of 80-130 lb-ft. Using a calibrated torque wrench is essential for achieving the correct tightening force and avoiding potential damage.

One of the main issues related to improper Wrangler wheel lug nut torque is wheel detachment. This dangerous situation can occur when lug nuts are not tightened sufficiently, allowing them to gradually loosen and eventually come off entirely. The consequences can be catastrophic, leading to loss of control and potential accidents.

Another common problem associated with incorrect lug nut torque is rotor damage. Over-tightening can warp the rotors, causing vibrations and reduced braking performance. This can necessitate costly repairs or even rotor replacement.

Benefit 1: Enhanced Safety - Correct torque ensures wheel stability, preventing detachment and potential accidents. Example: A properly torqued wheel remains secure even during challenging off-road conditions.

Benefit 2: Improved Performance - Correct torque prevents rotor warping, maintaining optimal braking performance. Example: Consistent braking performance contributes to a smoother and more controlled driving experience.

Benefit 3: Extended Component Lifespan - Proper torque prevents damage to studs, rotors, and wheels, maximizing their lifespan. Example: Avoiding over-tightening can significantly extend the life of your wheel studs.

Action Plan: 1. Acquire a calibrated torque wrench. 2. Consult your owner’s manual for the correct torque specification. 3. Tighten lug nuts in a star pattern. 4. Recheck torque after driving 50 miles.

Checklist: Torque wrench, Owner’s manual, Lug nut key (if applicable).

Step-by-Step Guide: 1. Position the vehicle on a level surface. 2. Loosen lug nuts slightly. 3. Place the torque wrench on the lug nut and tighten to the specified torque. 4. Repeat for all lug nuts in a star pattern. 5. Recheck torque after 50 miles.

Advantages and Disadvantages of Using a Torque Wrench for Wrangler Lug Nuts

| Advantages | Disadvantages |

|---|---|

| Accurate torque application | Initial cost of the wrench |

| Prevents over-tightening and damage | Requires proper storage and calibration |

Best Practices: 1. Use a calibrated torque wrench. 2. Follow the star pattern. 3. Re-torque after 50 miles. 4. Clean threads before tightening. 5. Inspect lug nuts regularly.

Real Examples: Various situations involving loose wheels, rotor damage, and other issues related to incorrect torque.

Challenges and Solutions: Various scenarios involving stripped studs, damaged rotors, and solutions for addressing these issues.

FAQs: General questions and answers related to Wrangler lug nut torque.

Tips and Tricks: Additional tips for achieving and maintaining correct lug nut torque.

In conclusion, mastering the art of Wrangler lug nut torque is a fundamental aspect of responsible Jeep ownership. It’s a seemingly small detail that has a profound impact on safety, performance, and the overall longevity of your vehicle. By understanding the correct torque specifications, utilizing a calibrated torque wrench, and following best practices, you can ensure your wheels are securely fastened, minimizing the risk of accidents and maximizing the enjoyment of your Jeep Wrangler. Don't underestimate the power of this simple yet crucial maintenance task. Take the time to learn and implement proper lug nut torquing procedures, and you'll be rewarded with a safer, more reliable, and ultimately more enjoyable driving experience. Ignoring this critical aspect of vehicle maintenance can lead to costly repairs, compromised safety, and potential disaster. Take control of your Jeep’s well-being and prioritize correct lug nut torque today.

Unlocking circuits understanding key switch diagrams

Unlocking atomic secrets worksheets and answer keys

Understanding wells fargo cashiers check limits